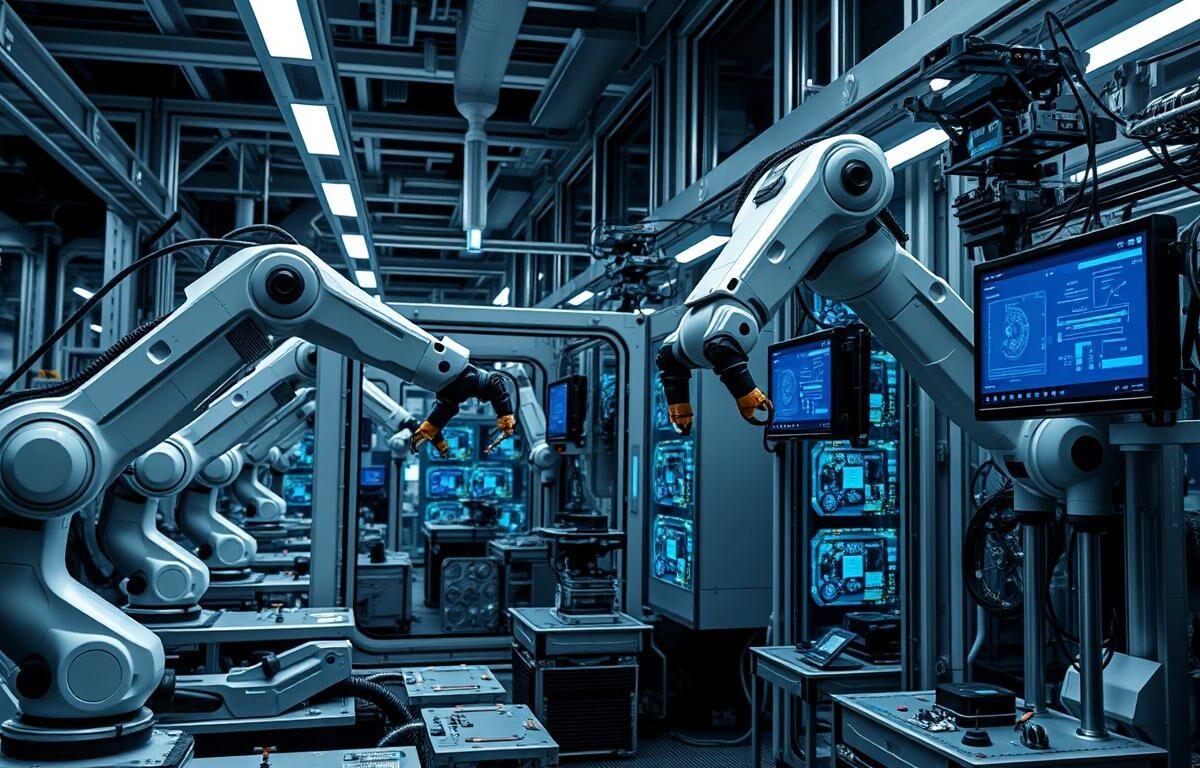

The manufacturing industry is facing a big change. This change is driven by new technology that makes production better and faster. Custom software for manufacturing is very important for this. It helps businesses stay ahead by using the latest manufacturing technology solutions. This leads to more work done in less time and lowers costs.

Businesses now use things like IoT for better production lines and AI for quality control. This kind of custom software is key to keeping an eye on everything, reducing stoppages, improving quality, and maintaining equipment before issues arise. ITMAGINATION, which works in software engineering and is a top partner of Microsoft for Application Development and Cloud Solutions, uses these technologies. They make the workplace safer and make sure companies follow rules. ITMAGINATION has helped big names like Kabbage (now part of American Express) and BNP Paribas. They’ve been doing this for over 20 years, offering smart software choices for manufacturing.

Key Takeaways

- Custom software boosts manufacturing by making it quicker and cheaper.

- Using IoT and AI means better oversight, less downtime, and smarter upkeep.

- Software tailored for safety and rules means a better workplace.

- ITMAGINATION brings 20 years of experience and Microsoft Gold Partner status to the table, with a skilled team available all the time.

- Adding custom software to manufacturing technology solutions raises profits and makes customers happier.

- For the changing needs of manufacturing, custom ERP software solutions with AI and ML are key.

Importance of Custom Software in Manufacturing

The manufacturing sector is always changing. It needs solutions that improve efficiency and meet complex market needs. Custom software development services are crucial for this industry. They help create automation software and other tools that solve manufacturing challenges.

Custom software allows manufacturing companies to make their operations smoother. It aids in everything from making things on the shop floor to delivering them.

Boosting Efficiency and Productivity

Custom software makes manufacturing processes better by automating simple tasks. It cuts down on manual work and mistakes. This improves both efficiency and productivity. For instance, using software for keeping track of inventory automates recording stock levels. This reduces time spent on inventory management.

Reducing Operational Costs

One big reason custom software is popular in manufacturing is that it lowers costs. It helps avoid downtime and use resources better. This makes manufacturers more efficient. Tools for planning production and monitoring in real time also help limit waste and use less energy. This leads to smarter manufacturing practices.

Enhancing Quality Control

Quality control is super important in making things. Custom software has tools for checking and analytics driven by AI. They can find possible flaws early in making products. This cuts costs by lowering the need for redoing work. It also keeps the quality of the final product high. This makes customers happy.

Custom software can really change the manufacturing industry for the better. Looking at how production efficiency and cost savings improve before and after it’s used shows its value.

| Parameter | Before Implementation | After Implementation |

|---|---|---|

| Production Efficiency | Modest | High |

| Operational Costs | Substantial | Reduced |

| ROI | Low | Significantly Increased |

| Quality Control | Standard | Enhanced |

Custom software doesn’t just affect one part of manufacturing. It leads to improvements all over. As companies keep using these solutions, they get ahead in a tough industry driven by tech.

Key Features of Custom Manufacturing Software

The manufacturing industry is changing fast, thanks to digital tech. Industry-specific software development plays a big role in this. Custom software for manufacturing has key features that meet the industry’s complex needs.

Integration with Existing Systems

Custom software stands out in manufacturing for working well with systems you already use. Think ERP, CRM, and accounting software. This makes things run smoother and cuts mistakes by automating common tasks. It keeps data flowing evenly and makes processes simpler. This means products stay consistent in quality with less human effort.

Real-Time Data Analytics

With custom software, you get to see data updates instantly. It has tools for predicting trends, managing inventory, and watching operations to quickly handle issues. Using these tools helps you make smart decisions and plan better. Manufacturing becomes more efficient and can adapt faster.

Supply Chain Management Tools

Custom software has advanced tools for managing how you get, make, and send products. These tools let you see what’s happening in your supply chain in real time. You can manage your inventory better, follow industry rules, and use mobile apps to handle things from anywhere. This fits today’s manufacturing world, which is always on the move.

| Feature | Description | Benefits |

|---|---|---|

| ERP Integration | Links with ERP systems to manage all business activities | Enhances operational efficiency, improves inventory management |

| Real-time Analytics | Predictive tools for trend analysis and issue anticipation | Facilitates proactive management, enhances quality control |

| Mobile Accessibility | Remote access and management through mobile platforms | Increases flexibility and on-the-go decision making |

| Compliance Automation | Automates adherence to industry standards and regulations | Reduces risk and ensures continuous compliance |

| Supply Chain Optimization | Advanced tools for managing supply chain operations | Improves supplier collaboration and inventory control |

Customizing and using these smart tools helps manufacturing businesses grow. They can handle new industry demands and challenges better. This strategic move supports expansion and adapts well to change.

Benefits of Implementing Custom Solutions

Choosing custom software for manufacturing brings big rewards. It boosts how well operations run and solves unique problems. Using custom solutions makes things smoother and helps a company be more flexible.

Tailored to Specific Business Needs

Custom software fits the manufacturing world perfectly. It changes to meet unique needs. It can improve how things are planned and keep quality high. For certain fields like aerospace or biotech, it manages complicated steps while following strict rules.

Improved Flexibility and Scalability

The ability to grow and change is key in business. Custom software helps manufacturers scale easily. A Capterra study shows 61% of them prefer solutions they can tailor. This makes it easier for businesses to grow and adapt.

Streamlined Processes and Workflows

Manufacturing software aims to make work smoother. It brings data together, automates tasks, and improves team communication. This keeps errors low and avoids data issues. The result? Fewer delays and better overall operations.

| Feature | Benefits |

|---|---|

| Real-Time Data Insights | Enables proactive management of production lines and inventory, reducing downtime and waste. |

| Custom HR Modules | Improves team management and operational communication, essential for complex manufacturing settings. |

| Advanced Security Protocols | Ensures data integrity and safety, critical for industries handling sensitive information like aerospace and pharmaceuticals. |

| Predictive Maintenance | Increases equipment lifespan and efficiency, crucial for sustained manufacturing productivity. |

Selecting the Right Software Development Partner

Finding the perfect partner for custom software development services is key in manufacturing. This sector’s complexity requires a partner with industry know-how. Choosing one with relevant experience and expertise is critical for companies.

Industry Experience and Expertise

Partners must understand manufacturing sector software solutions well. This includes automation of the production line to managing the supply chain. A knowledgeable partner boosts efficiency with tailor-made software for manufacturing.

Proven Track Record and Case Studies

It’s crucial to check a partner’s past work and client feedback. Success in similar sectors shows their ability to deliver strong, effective solutions. Their portfolio shows their skill, adaptability, and reliability in facing industry-specific problems.

Customer Support and Maintenance

Support after launching is vital for software development. Gartner says 60% of firms face big problems six months after launch without good support. Continuous support and maintenance are key so the software can grow with your business and industry changes.

When picking a software development partner for manufacturing, compare these important factors:

| Criteria | Importance | Notes |

|---|---|---|

| Expertise in Manufacturing | High | Look for partners familiar with the manufacturing sector. |

| Proven Track Record | High | They should have a history of success in manufacturing-related projects. |

| Support and Maintenance | Crucial | They need to offer ongoing support for any issues that come up. |

| Cost Efficiency | Medium | Prices should be clear and fit within your budget. |

Picking the right custom software development partner affects both immediate project results and long-term growth. Begin with a clear plan, focus on important criteria, and aim for a joint effort. This will lead to success in custom software development services.

Custom Software Development Process

The journey to make custom software for the manufacturing industry starts step by step. This method brings powerful solutions designed to make industrial work better. This special method not only fits unique business needs but also works well with manufacturing automation software. It helps manufacturers do their jobs better.

Initial Consultation and Requirement Analysis

The first step in making custom software is a deep talk about what’s needed for software for industrial production. This part is very important. It helps us understand the unique problems and goals of a manufacturing business. This makes sure the solution fits their workflow perfectly.

Design and Prototyping

After talking about what’s needed, we move to designing and making a prototype. We focus on making user-friendly designs. Imagine how users will use the system. Making a prototype gives us something we can see and touch. It lets us get feedback to make sure the software does what it should for the business.

Testing and Implementation

The making of custom software for the manufacturing industry includes thorough testing. This testing makes sure the software works great on all platforms and meets all standards. Then, the software is put to work in real situations. This is where it starts to improve how manufacturing works.

By adding these custom software solutions, manufacturers can work much more efficiently. They get more automation in making things, which really shows in their performance and cost management.

| Feature | Benefits | Provider |

|---|---|---|

| Predictive maintenance | Prevents workflow issues, reduces downtime | Integrio Systems |

| AI-powered tools | Enhances process efficiency, predicts risks | Integrio Systems |

| All-in-one dashboard | Instant access to project specifics and KPIs | Cam Tran |

| Custom UI/UX | Engages and motivates employees | Integrio Systems |

| Integration with major IT players | Ensures top-tier quality and innovation | Emerline |

This thoughtful method does more than just meet industry standards. It changes how things are made with smart automation and the latest tech.

Challenges in Custom Software Development

Starting with custom software development services for manufacturing brings many challenges. It involves managing costs, handling changes, and meeting deadlines. This ensures top-notch manufacturing sector software solutions.

Cost Considerations

Creating software just for manufacturing requires a lot of money and resources at the start. Companies must find a balance. They need to innovate without spending too much.

Change Management Issues

Introducing new tech can shake up current methods. It’s vital to have good change plans and train employees well. This helps operations smoothly switch to the new system.

Time Constraints

Projects often have tight deadlines. Delays can impact the whole organization, messing up schedules and deliveries. Aligning development with business goals is thus crucial.

| Solution Type | Outcome Increase (%) | Operational Improvement (%) |

|---|---|---|

| Custom MES Solutions | 20 | 15 |

| Custom QMS Solutions | 25 | 30 |

| Predictive Maintenance Software | 20 | 40 |

| ERP Systems | visibility improvement | cost reductions |

| WMS Systems | optimized stock management | shipment efficiency |

On this journey, refining and implementing tailor-made software for manufacturing is full of challenges. It calls for a strong strategy and a dependable software development ally.

Future Trends in Manufacturing Software

The world of manufacturing is changing fast, thanks to new tech and smart software. Companies now must use advanced manufacturing technologies and software to keep up and thrive. This includes using industry-specific development and custom software designed for manufacturing.

AI and Machine Learning Integration

AI and machine learning are changing what custom software can do in manufacturing. They make it easier to prevent machine breakdowns, ensure products are high quality, and plan production. With AI, factories can see problems coming and fix them early. This lowers the time machines are down and saves money.

IoT and Smart Manufacturing

The Internet of Things (IoT) is key to creating smarter manufacturing plants. It allows for more automation and connection in the production process. Experts believe half of all manufacturers will be using IoT by 2025. This shows how important IoT is for making operations more efficient and making better decisions with data.

Cloud Solutions and Remote Accessibility

Cloud computing is changing how manufacturers handle data and operations. This technology gives scalable, remote access to data, helping teams work together in real time, no matter where they are. It helps operations keep going smoothly and cuts down costs related to old-school IT setups.

This table shows what experts think about different new technologies and their effects on manufacturing. They look at how each one can make operations better and help companies win against competition.

| Technology | Impact on Efficiency (%) | Impact on Competitiveness (%) |

|---|---|---|

| IoT | 75 | 70 |

| AI/ Machine Learning | 85 | 80 |

| Cloud Solutions | 65 | 60 |

| Robotics | 90 | 88 |

| 3D Printing | 55 | 50 |

| AR/VR | 47 | 50 |

In conclusion, as manufacturing continues to evolve, AI, IoT, and cloud tech remain crucial. Manufacturing technology solutions and industry-specific software development need these technologies to meet market demands. They help improve efficiency, spur innovation, and boost competitiveness worldwide.

Case Studies: Successful Implementations

Exploring case studies shows us the real value of custom software in manufacturing. Leaders in the industry have used software to change how they operate. For example, Amazon used custom software to improve how it serves customers. This led to saving money and making customers happier. Similar strategies work well in industrial production too. Custom solutions boost efficiency and reduce costs.

Example 1: Increased Efficiency

In the manufacturing world, being efficient is key to doing well. Boeing is a great example. They used custom software to make production faster and keep quality high. Armstrong Industrial Corporation saw a 30% rise in how much they could produce by adding IoT systems and analyzing data in real time. These examples show how the right software can greatly improve how much and how well factories produce.

Example 2: Cost Reductions

Custom software also helps cut costs. Armstrong Industrial Corporation used technology to predict maintenance, reducing downtime by 35%. This saved money on delays and repairs. They also cut down on wasted materials and energy by 20%. These savings show the financial benefits of using custom software to better manage resources.

Lessons Learned and Best Practices

The stories of success with software share important lessons for manufacturers. Aligning software with business goals is crucial, as seen with Uber and Airbnb. Using real-time data, predictive analytics, and flexible project management is also key. Companies like Armstrong Industrial Corporation and Skirtings R Us illustrate this point. Investing wisely in custom software can give companies a lasting edge in a very competitive market. By 2030, the manufacturing sector in the U.S. alone could be worth over $944.6 billion with over 700,000 companies competing for the top spot.

FAQ

What role does custom software play in the manufacturing industry?

Custom software boosts manufacturing operations by improving productivity and cutting costs. It allows for real-time monitoring and better production process optimization. This includes integrating IoT and AI for improved quality control and making supply chain management smoother.

How does custom software improve efficiency and productivity in manufacturing?

Custom software increases efficiency by enabling real-time management of resources and automating key tasks. It makes production lines better, ensures predictive maintenance, and reduces downtime. All these are possible with software tailored for manufacturing.

What are the cost benefits of implementing custom manufacturing software?

Implementing custom software helps reduce operational costs by lowering downtime, using staff more efficiently, and better resource management. It also cuts down rework costs by catching defects early, improving product quality.

What key features should be considered in custom manufacturing software?

Important features include easily working with existing systems, using real-time data analytics for smarter decisions, and offering advanced tools for managing the supply chain. It should also be flexible to meet the manufacturing sector’s evolving needs.

What are the benefits of choosing tailor-made software solutions for manufacturing?

Choosing tailor-made software brings many benefits. It provides custom features that meet specific business needs, supports growth through scalability, and streamlines operations to boost performance.

How to select the right software development partner for manufacturing software?

Choose partners who have industry knowledge and a solid track record, like ITMAGINATION. Check their portfolio of successful projects. Also, consider their commitments to customer support and maintenance for a reliable long-term partnership.

What is the process of custom software development in manufacturing?

The development process starts with a consultation and risk check. Next comes design and prototyping, followed by iterative development. After rigorous testing, the software is implemented successfully, with continuous support offered.

What are the challenges involved in developing custom software for manufacturing?

Developing custom software comes with challenges like keeping project costs in check, dealing with changes efficiently, and sticking to schedules to avoid expensive delays. Companies like CSW Solutions are experienced in overcoming these issues with strong supportive practices.

What future trends are shaping custom manufacturing software?

Future trends include using AI and machine learning for smarter scheduling and quality checks, IoT for advanced manufacturing processes, and cloud solutions for better collaboration and access from anywhere. These tech advancements drive continuous innovation and adaptability in manufacturing software.

Can you provide examples of successful custom software implementations?

Successful examples include IoT systems that have reduced equipment downtime and AR mobile apps that have led to fewer maintenance errors. These show how technology aligned with business goals can enhance efficiency and save costs.