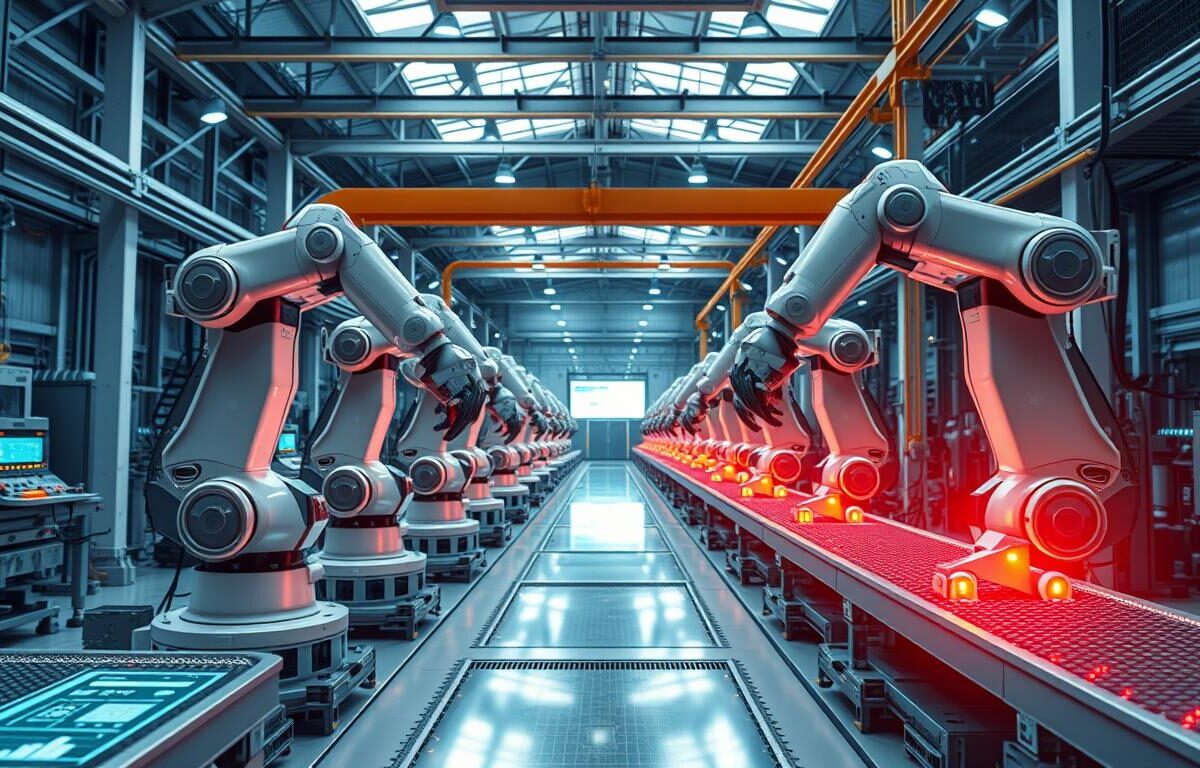

AI agents are changing the game in manufacturing. They use smart machine learning to understand their surroundings. This lets them handle operations, do tasks on their own, and make everything more efficient.

Smart factory technology relies greatly on AI agents today. They help with smart choices and predicting future needs, which changes how factories work. Little to no human help means more accuracy and fewer mistakes.

Using AI agents in manufacturing makes production, maintenance, and quality control better. This leads to great increases in how well and how much factories produce.

AI agents are now a key part of Industry 4.0 tools and technologies. They look at supply chain data, guess demand changes, and improve how inventory is managed. This brings big benefits to manufacturing operations.

Key Takeaways

- AI agents enhance operational efficiency by automating tasks and reducing human errors.

- Smart decision-making capabilities of AI agents support proactive maintenance, minimizing costly downtimes.

- AI robots in manufacturing offer superior quality control through precise inspection, reducing production errors.

- Effective use of AI agents forecasts demand, optimizes inventory, and streamlines supply chain management.

- AI agents in manufacturing contribute to improved worker safety by identifying hazards and suggesting safety practices.

- Regular monitoring and optimization are crucial for maintaining the effectiveness of AI agents in ever-changing manufacturing environments.

Understanding AI Agents in Manufacturing

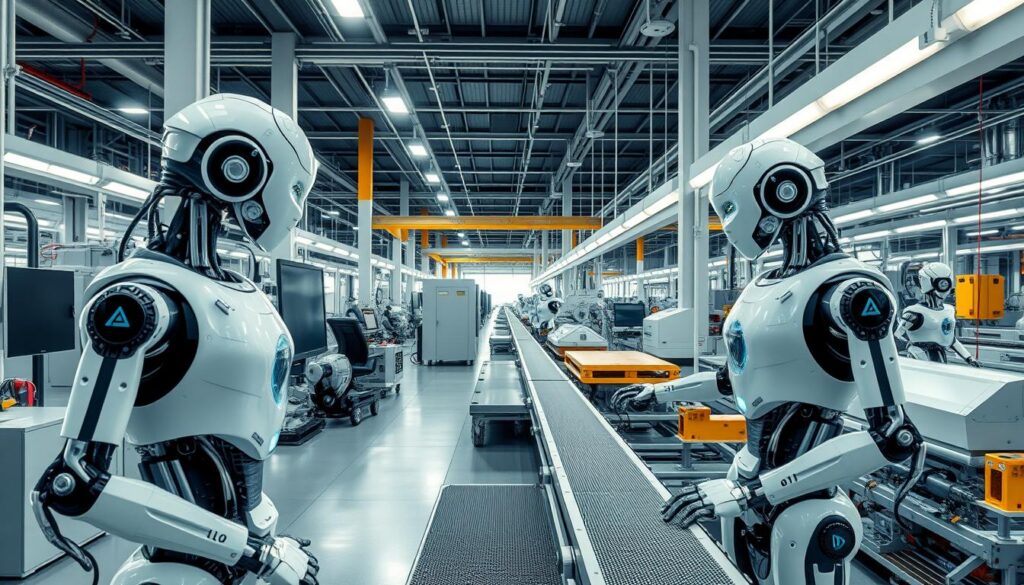

AI agents are innovative tools. They work on their own to perform tasks in manufacturing. These systems handle data, make smart choices, and improve how factories operate. They solve problems and make decisions well. This helps factories become smarter and more efficient.

What are AI Agents?

AI agents use artificial intelligence to do tasks without human help. They follow set goals and analyze data in real-time. These agents handle collecting data, automating processes, making decisions, and communicating. They improve production schedules and equipment upkeep. They boost factory efficiency overall.

The Role of AI Agents in Factories

In modern manufacturing, AI agents automate simple and complex tasks. Here’s how they help factories:

- Predictive Maintenance: They forecast equipment issues to cut downtime and save on costs.

- Quality Control: AI-driven checks find defects early. This reduces waste and makes customers happy.

- Production Optimization: They make production smoother, ensuring top efficiency and safer working conditions.

- Data-Driven Decision Making: By analyzing data, they offer valuable advice. This helps manage stock, predict needs, and choose the best suppliers.

- Customization and Adaptation: AI agents tailor manufacturing to customer likes and adjust to market changes.

The AI market in manufacturing was worth USD 3.8 billion in 2022. It’s expected to reach about USD 68.36 billion by 2032. This growth, at a rate of 33.5% a year, underlines AI agents’ crucial role. They bring top efficiency, quicker innovation, and adapt quickly to market needs.

| Key Benefits | Description |

|---|---|

| Predictive Maintenance | They predict when equipment might fail. This reduces downtime and saves money. |

| Quality Control | Early defect detection improves quality and lessens waste. |

| Production Optimization | Makes things run smoother and production schedules better. |

| Data-Driven Decision Making | Gives insights for better inventory management, demand forecasting, and choosing suppliers. |

| Customization and Adaptation | Adjusts manufacturing for customer preferences and market shifts. |

AI agents learn and adjust to keep factories running well, even when markets change. They are key to smart automation and making factories better.

How AI Agents Enhance Operational Efficiency

AI agents bring a big change to the manufacturing world. They make operations run smoother, faster, and cheaper by using robotics for industrial automation and smart factory technology. This leads to more work getting done with less effort.

Streamlining Production Processes

AI helps make manufacturing smarter. It uses data to improve how factories work, making things faster with less waste. This makes products better and saves time. Experts think AI will automate 80% of jobs in factories by 2025. This means factories will run more smoothly and with fewer problems. The use of smart factory technology is a big part of this change.

Optimizing Workflows and Reducing Bottlenecks

AI looks at how work is done and finds ways to improve it. This helps factories run without stopping, making more products faster. AI adjusts plans on the fly to keep up with changes. It also spots where resources are wasted and suggests improvements. This leads to faster development of new Industry 4.0 tools and technologies, speeding up innovation by 30%.

Improved Worker Safety and Efficiency

AI makes workplaces safer by spotting dangers before they happen. This keeps workers safe and avoids work stoppages. Using machine learning in production, AI quickly handles issues to keep things moving smoothly. It also helps keep products up to standard. So, AI is key for keeping workers safe and making things run well.

| Parameter | Benefit |

|---|---|

| Production Process | Optimized sequences, reduced waste, enhanced throughput |

| Workflow Optimization | Reduced bottlenecks, improved productivity, dynamic scheduling |

| Worker Safety | Hazard prediction, prevented interruptions, safer workspace |

| Quality Control | Real-time monitoring, deviation detection, high-quality output |

AI Agent for Manufacturing: Revolutionize Ops.

Artificial intelligence is changing how factories work. It makes decisions in real time, predicts when machines will need fixing, and keeps product quality high. AI in factories increases efficiency, cuts downtime, and guarantees great products.

Real-Time Decision Making

AI agents make quick decisions by studying data from many sources. This helps factories act fast when problems arise, keeping things running smoothly. With AI, factories quickly adjust to new market trends and what customers want. This makes them more resilient and competitive.

Predictive Maintenance

AI predicts when machines will break before it happens. This means less sudden downtime and longer-lasting equipment. This smart approach saves money, boosts reliability, and keeps factories running well. AI analyzes data to keep machines in top shape, reducing stops in production.

Enhancing Quality Control

Quality control is better with AI. AI tools give detailed checks on products as they’re made. They find and fix faults with great precision, ensuring only the best products are sold. AI also reviews reports and documents to keep improving quality and solving problems before they happen.

AI helps factories not just meet, but go beyond their quality goals. This makes them stand out in a tough market.

| Feature | Impact |

|---|---|

| Real-Time Decision Making | Immediate response to anomalies, optimized performance |

| Predictive Maintenance | Reduced downtime, extended machinery lifespan, cost-saving |

| Enhancing Quality Control | High-quality product output, reduced defects, improved standards |

Implementing AI Agents in Manufacturing

Adding AI to manufacturing is more than just a tech step. It’s a key move that can change operations dramatically. About 35% of manufacturers will likely use AI in the next five years. This is because AI offers huge benefits for operations.

“AI agents in manufacturing can lead to unprecedented levels of production and product quality through the use of multi-agent systems (MAS) and machine learning algorithms, enhancing every aspect from supply chain management to equipment maintenance.”

To start with industrial automation, first set clear goals. Then pick the right tech. It’s important to choose AI-ready software. And to train it with lots of data.

- Selecting AI-compatible software: Choose systems that fit easily with what you already have.

- Robust data protocols: Use detailed data sets for training, so the AI works its best.

AI gets better as it learns more. Learning agents improve with experience. This is very helpful in changing situations. For quality checks, AI uses smart vision and deep learning. It finds flaws in products with great accuracy.

AI also boosts how well operations run. It looks at maintenance records and sensor data. This predicts problems and makes things run smoother. AI can also cut energy costs. It does this by scheduling equipment better.

| Aspect | Benefit of AI Agents |

|---|---|

| Cost Efficiency | Lower operation costs through optimized equipment utilization |

| Predictive Maintenance | Reduce downtimes by predicting equipment failures |

| Product Quality | Enhanced detection of product defects using machine vision |

| Operational Efficiency | Streamline production through subdivision of tasks |

Using AI in automation gives companies an edge. The market for this is expected to hit about USD 68.36 billion by 2032. It’s clear AI will keep playing a big role in manufacturing’s future.

Conclusion

Integrating AI into manufacturing brings big changes. It makes operations better, keeps workers safe, and improves quality control. By using smart systems, makers can enjoy the big advantages of AI in the. This includes doing repeat tasks easily, better supply chain management, and smarter decision-making.

AI doesn’t just make production smoother but also cuts costs a lot. A study showed a 20% cut in costs for companies using AI in their first year. Also, AI can predict when machines need fixing, reducing downtime by up to 30%. This huge boost in work shows how important AI is for the future of making things.

In the world of Industry 4.0, using AI is key to keep up. It lets companies change production based on fresh data, guess how well suppliers will do, and handle stock better. These are a few reasons why AI is vital for modern manufacturing to grow. Accepting AI not only makes operations excellent but also readies makers for the future of making things.

FAQ

What are AI Agents?

AI agents are smart systems that make their own decisions. They make factories work better by analyzing data. They do this with little help from humans.

What role do AI Agents play in factories?

AI agents help manage and run factories. They make smart choices and use data to improve tasks. This makes the factory work better and more efficiently.

How do AI agents streamline production processes?

AI agents use data to make production lines better. They help make more products and improve quality. They do this by reducing waste and being precise.

How can AI agents optimize workflows and reduce bottlenecks?

AI agents look at how work flows to find and fix slowdowns. This makes the manufacturing smoother and more productive.

How do AI agents improve worker safety and efficiency?

AI agents keep workers safe by watching for dangers. They predict problems to keep the workplace safe. This helps avoid accidents and keeps things running smoothly.

What are the benefits of real-time decision-making enabled by AI agents?

AI agents look at data from many places right away. This helps them act quickly to keep things running well. This means the factory can adjust quickly and work better.

How does predictive maintenance work with AI agents?

Predictive maintenance uses AI to predict when machines might break. This helps fix things before they cause problems. It saves money and keeps machines working longer.

How do AI agents enhance quality control in manufacturing?

AI agents check products as they’re made to catch problems early. This helps make sure everything meets high quality standards. It keeps quality consistent before reaching customers.

What are the steps involved in implementing AI agents in manufacturing?

To use AI agents, you need a plan. Pick the right AI, train it with lots of data, and make sure it fits well with your current systems. Good data handling is key for a smart, flexible factory.